20+ Years

Packaging solution experience

1000+ Projects

500+ Clients

100%

Custom Packaging Styles

Package N’ Go offers a diverse range of packaging solutions tailored to meet your unique requirements. Whether you’re in search of custom poly mailers or custom boxes, we’ve got you covered with a comprehensive selection of options to choose from.

Why you can rely on package n' go

What makes us the preferred choice for over 500 clients worldwide?

- Eco-friendly materials

- Low MOQ

- Free Design

- Exceptional cost-effectiveness

- 24/7 Customer Service

Our Trusted Brand Partners

What Our Clients say

Trip Martins

Cathy Green

Randy Jackson

Latest Blogs

11 Questions You May Ask About Honeycomb Paper Bags

What is a honeycomb paper bag? A honeycomb paper bag is an advanced packaging solution composed of three distinct layers: two outer layers of kraft paper and a core layer of honeycomb paper. The honeycomb paper, crafted …

7 Questions You May Ask About Biodegradable Poly Mailers

What is a biodegradable poly mailer? A biodegradable poly mailer is an environmentally friendly packaging solution made from materials that can naturally break down over time. Unlike traditional plastic mailers, which ca…

10 Questions You Want to Ask About Zip Lock Bags

Table of Contents What is a Zip Lock Bag? A zip lock bag is a versatile type of plastic packaging commonly used for items like clothing, shoes, bags, food, cosmetics, medicines, and more. Its standout feature is the zip-…

What is a Glassine Bag And How Can it Help Your Business

Table of Contents Glassine bags are an essential packaging solution in numerous industries due to their unique properties and versatility. Crafted from high-quality glassine paper, these bags are known for their dense, u…

Everything You Need to Know About Gravure Printing

Table of Contents 1. Introduction to the Process Gravure printing is a direct printing method where ink from the recessed cells of the gravure cylinder is transferred directly onto the substrate. In gravure printing, the…

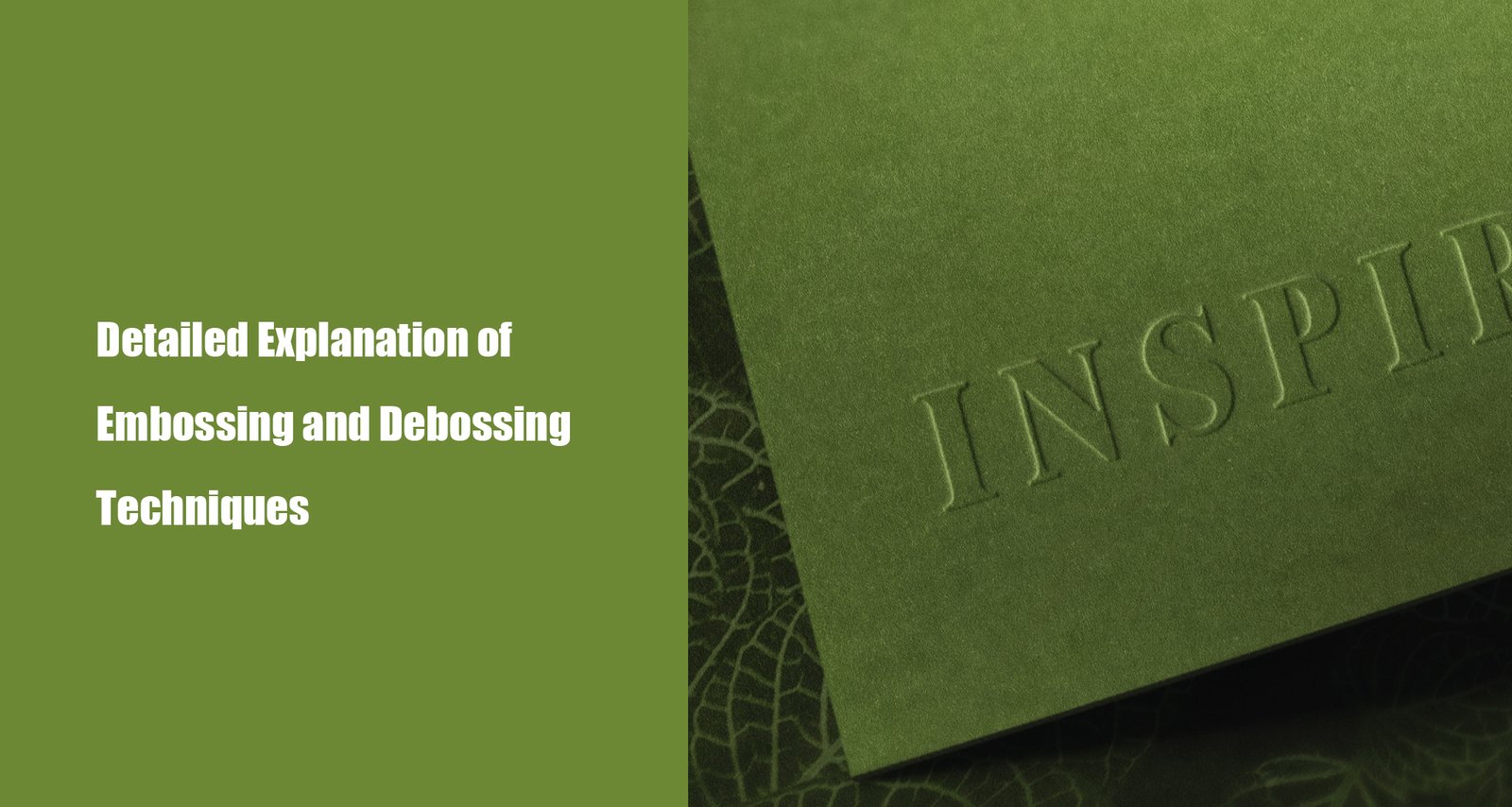

Detailed Explanation of Embossing and Debossing Techniques

Table of Contents 1. Introduction to the Technique Embossing and debossing, also known as relief printing or raised printing, are post-press techniques that create a three-dimensional effect on paper or other substrates.…

Die-Cutting Process for Paper Products

Table of Contents 1. Process Overview The die-cutting process is a critical technique in paper product processing. It utilizes molds to cut paper, cardboard, and other materials into specific shapes and sizes. Currently,…

Detailed Explanation of the Lamination Process

Table of Contents Introduction to the Process Principle Lamination is a surface finishing process in printing, also known as post-press coating, post-press lamination, or post-press film application. It involves cove…

Everything You Need to Know About Biodegradable Poly Mailers

Table of Contents Chapter 1: Understanding biodegradable poly mailers 1.1 What is a biodegradable poly mailer? A biodegradable poly mailer is an eco-friendly packaging option made from biodegradable materials. It can…

The Ultimate Guide to Shipping Box

Table of Contents Chapter 1: Understanding shipping boxes 1.1 What is a shipping box? The shipping box has a straightforward design, formed by folding and creasing a single piece of cardboard. It includes four three-…

How do custom bubble mailers provide cushioning and protection for items?

Custom bubble mailers have gained popularity as a packaging option due to their ability to withstand the harsh realities of shipping. Whether it is to cushion fragile items or to protect goods during transit, these envelopes are a reliable solution. Their unique structure allows for

How To Choose The Right Bubble Mailer For Your Shipping Needs

Nothing is more important when mailing products than making sure they are safe throughout transportation. Achieving that goal can be greatly aided by selecting the proper type of bubble mailer. In this post, we hope to provide you with a thorough guide to help

Cold Or Hot? Exploring The Benefits Of Foil Stamping

Are you looking to add an extra touch of luxury to your product packaging? Have you considered foil stamping as a potential option? Foil stamping is a popular choice for businesses due to its ability to add depth and texture to packaging designs. But what

How do custom bubble mailers provide cushioning and protection for items?

Custom bubble mailers have gained popularity as a packaging option due to their ability to withstand the harsh realities of shipping. Whether it is to cushion fragile items or to protect goods during transit, these envelopes are a reliable solution. Their unique structure allows for

Upgrade your packaging today!

strategy for protecting your products and promoting your brand.