In the vibrant realm of product businesses, where imagination takes shape and innovation comes to life, packaging stands as a silent yet dynamic force that can make or break your success. It is the art of wrapping your passion, your dedication, and your creativity into an alluring exterior that captures hearts and entices minds.

But beware, fellow entrepreneurs, for even the most ingenious products can fall victim to the treacherous traps of packaging blunders. Fear not, for we have embarked on a quest to uncover the 15 most common packaging mistakes that plague our industry, equipping you with the knowledge and guidance to avoid these pitfalls.

Get ready to embark on a journey where design, functionality, and customer satisfaction converge, paving the way for your products to shine brighter than ever before.

- Oversized Boxes

Do you think bigger equals better? Do you follow the policy of “one size fit all”? If so, correct it before it’s too late. The bigger doesn’t means the better, but the fit does. Boxes larger than necessary not just cost you much but annoy their end-users as well. Imagine that you are unwrapping a large box, expecting that a big surprise is waiting for you, but the result is just a tiny item. What a huge gap!

Besides, oversized boxes give your products more room to move around, which are potential to be damaged during transit.

How to Do

a) Right-sizing: Evaluate the dimensions of your products and choose a box that fits them snugly. Measure the length, width, and height of the item and select a box that provides just enough space for proper cushioning materials. This will prevent excessive movement and minimize the risk of damage.

b) Consider weight limits: Take into account the weight of your products and choose a box that can withstand the weight without compromising its structural integrity. Use reinforced corrugated boxes for heavier items to ensure adequate support during transit.

Remember, the goal is to find the right balance between protecting your products and optimizing the use of packaging materials. Avoid oversized boxes to reduce costs, prevent damage, and ensure a positive experience for your end-users.

- Complicated Packaging

Just think about how your customers would feel if they get an item out of packaging with excessive bubble-wrap and twist ties. The hard-to-open packaging is most likely to bring immense frustration and an unpleasant experience for your consumers.

Excessive packaging leads to excessive waste. In this world that everyone pursues environmental protection, if you are against the culture with difficult packaging, it is ultimately damaging for your business growth. Make your corporate culture different in a positive way instead of a negative way.

How to Do

a) Easy-to-remove seals: Use seals that are designed to be easily peeled off or opened without the need for additional tools. These could include adhesive strips that can be easily pulled apart or perforated tear strips that allow for effortless opening.

b) User-friendly closures: Opt for packaging closures that are intuitive and easy to open. For example, consider using flip-top lids, slide-out trays, or resealable zippers that can be opened and closed without much effort.

c) Clear instructions: Provide clear and concise instructions on how to open the packaging. Include diagrams or illustrations if necessary to guide customers through the unboxing process. Make sure the instructions are prominently displayed on the packaging to avoid confusion.

d) Balance security and convenience: While it’s important to have easy-to-open packaging, it’s equally crucial to maintain the security and protection of the contents. Find the right balance between security and convenience by using tamper-evident features or protective inserts that can safeguard the product while still allowing for easy access.

- Unbranded boxes

Do you think the main functions of packaging are just protection and containment? If so, you’re missing out that a box can also serve as a marketing tool to help promote your products. Research shows that the right packaging and messages can stimulate impulse buying.

With that said, you must seize the opportunity to communicate about your brand and company’s story with custom boxes. Branded packaging with messages can differentiate your products from that of other competitors.

How to Do

To make the most of your packaging, it’s essential to consider branding as a valuable aspect. Here’s how you can utilize custom boxes to promote your products and communicate your brand effectively:

a) Design a branded box: Create a visually appealing and recognizable design for your packaging that reflects your brand identity. Incorporate your logo, company colors, and any other relevant branding elements. This will help customers associate the product with your brand and increase brand recognition.

b) Tell your brand story: Use the packaging as an opportunity to share your brand’s story and values. This can be done through the use of text, images, or even QR codes that lead customers to your website or social media platforms where they can learn more about your brand.

c) Consistency across channels: Ensure that your packaging design aligns with your overall brand image across all marketing channels. This consistency helps build trust and reinforces brand recognition.

Remember, packaging is not just about protection and containment but also an opportunity to create a lasting impression and engage with your customers on a deeper level.

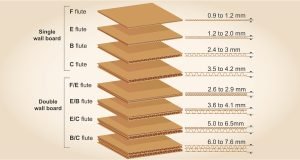

- Wrong materials

Selecting the wrong materials is repeated time and again by a large number of manufacturers. One of the main reasons that branding elements do not look their best is the wrongly chosen materials.

When it comes to corrugated boxes, you mainly have three materials and five cardboard flute thicknesses to choose. (Besides, numerous fancy paper types are available, primarily for rigid boxes.)

Kraft cardboard with a classic brown look is not friendly to color-heavy images. Some companies who use this kind of cardboard to print bright colors resulted in the images are muted.

Single-walled cardboard doesn’t suitable for all. Choosing cardboard that is not thick enough can cause damage to the box and to your products.

How to Do

a) If you are selling organic goods:

- The natural brown look of kraft matches well with organic products, creating a cohesive brand image.

- Choosing kraft boxes can raise brand awareness and convey a sense of sustainability.

b) If you are pursuing great presentation of your design:

- The standard white option can fulfill your demand.

- Standard white boxes provide a clean and professional look.

c) If you are pursuing a better effect:

- Premium white boxesare brighter and glossier compared to standard white.

- Choosing premium white boxes can enhance the visual impact of your packaging design.

- Inadequate packaging

Using materials that are not designed to withstand the weight of your items can lead to catastrophic failures. Take shipping heavy machinery, for example; while lightweight, flimsy paperboard boxes may optimize convenience and cost timelines, they are far less likely to be able to support the weight and rigors of transport and delivery compared to their reinforced corrugated counterparts.

Trusting in a weaker option will undoubtedly pass on headaches such as box breakage or potential damage incurred by the cargo itself due to unsuitability.

How to Do

The most frequent packaging for goods is paperboard boxes, which gives you the most opportunity to directly communicate with your clients about what’s inside. Even though you chose the thickest material, it is not acceptable for shipment.

Corrugated boxes, such as shipping boxes or mailer boxes, is necessary to package your product. Mailer boxes don’t even require a paperboard box inside because it can be fitted with specially made inserts to safeguard your product.

Of course, you have access to a wide variety of additional box types. Rigid boxes are the perfect option if you want to give your product a more upscale appearance or turn it into a gift. However, you should also package them in corrugated boxes for a better appearance of your product.

- Ignoring Legal Requirements:

Every country has specific regulations regarding packaging materials. For instance, certain regions strongly advocate or enforce the use of packaging materials derived from recycled ocean plastics. In other areas, there are strict mandates to utilize paper sourced from certified sustainable forestry management or recycled pulp in order to minimize the depletion of natural resources.

Failing to comply with local laws and regulations can have severe consequences, potentially rendering your purchased materials unusable and resulting in significant financial losses.

How to do

Selecting a packaging supplier that demonstrates a strong commitment to adhering to various countries’ laws and regulations is crucial. When evaluating potential suppliers, it is essential to examine the qualifications they can provide as evidence of their compliance with local regulations. Look for suppliers who can offer the following:

a) Certifications and Compliance Documents: Check if the supplier possesses certifications or compliance documents that validate their adherence to specific packaging regulations. These certifications could include ISO certifications, REACH compliance, or other relevant industry-specific certifications.

b) Material Sourcing Transparency: Inquire about the supplier’s sourcing practices to ensure that the materials used in their packaging align with local regulations. They should be able to provide documentation and information about the origin and sustainability of the materials they utilize.

c) Testing and Verification: Verify if the supplier conducts regular testing and verification of their packaging materials to ensure compliance with local regulations. This could involve testing for restricted substances, strength and durability tests, or any other relevant assessments.

- Lack of Clear Instructions:

Including clear and concise instructions in your product packaging is crucial to guide your customers effectively. Neglecting to provide proper assembly or handling instructions can result in customer frustration, confusion, and even potential damage to the product.

How to do

a) Highlight safety precautions: If your product involves any potential hazards or safety considerations during assembly or use, it is vital to include explicit warnings and precautions on the packaging. This helps protect both the customer and your company from liability issues.

b) Use visual cues: Incorporate visual cues on the packaging to guide customers on proper handling or usage. For example, if the product has fragile components, include symbols or icons indicating the need for careful handling or the presence of delicate parts.

c) Ensure multilingual instructions if necessary: If your product is intended for a global market, consider including instructions in multiple languages to cater to a wider customer base. This demonstrates inclusivity and helps overcome language barriers.

d) Include contact information: In case customers have any questions or need further assistance, provide contact information such as a customer service hotline or email address. This helps establish a channel for communication and enhances customer satisfaction.

- Lack of Visual Differentiation

In a highly competitive market, knowing how to create eye-catching packaging is crucial to capturing the attention of potential customers and distinguishing your product from similar offerings. Failing to stand out visually can result in your product appearing generic or unremarkable, which can negatively impact sales and brand recognition.

How to do

a) Unique Design: Create a packaging design that is distinctive and memorable. Incorporate visually appealing elements, such as vibrant colors, interesting patterns, or eye-catching graphics. Ensure that the design reflects the essence of your product and communicates its unique selling points effectively.

b) Marketing messages: Take advantage of the packaging space to communicate key marketing messages. This can include product benefits, unique selling points, promotional offers, or any other information that can entice customers and create a desire to purchase.

c) Innovative Shapes and Structures: Consider using unconventional packaging shapes or structures that stand out on the shelves. This can attract attention and pique the curiosity of potential customers. However, ensure that the shape or structure doesn’t compromise the functionality or practicality of the packaging.

d) Visual Hierarchy: Use visual hierarchy techniques to guide the viewer’s eye and emphasize important information or product features. This can be achieved through the use of varying font sizes, colors, or placement of elements on the packaging.

- Ignoring Sustainability

In today’s environmentally conscious world, ignoring sustainability in packaging can have detrimental effects on your business. Consumers are increasingly prioritizing eco-friendly practices and actively seeking out products with sustainable packaging. How to design sustainable packaging is a crucial question to address. Failing to adopt sustainable practices not only harms the environment but also risks negative consumer perception, leading to lost sales opportunities.

How to do

a) Material selection: Opt for eco-friendly materials such as recycled paperboard, biodegradable plastics, or compostable packaging materials. These alternatives help reduce waste and minimize the environmental impact of your packaging.

b)Printing Techniques: It is also important to consider the use of eco-friendly printing inks and postpress when designing patterns for printing apart from selecting eco-friendly materials. It is advisable to avoid lamination whenever possible and opt for aqueous coating instead.

c) Reduce packaging waste: Minimize the amount of packaging material used while still ensuring the safety and protection of the product. Knowing how to reduce packaging waste is essential as excessive packaging not only contributes to environmental issues but also leads to higher shipping costs.

d) Inform and educate consumers: Clearly communicate your commitment to sustainability through labeling and packaging design. Use symbols or statements that highlight the eco-friendly features of your packaging, such as “recyclable,” “made from recycled materials,” or “biodegradable.”

- Incorrect Barcodes or QR Codes:

Barcodes and QR codes play a crucial role in inventory management and tracking systems. However, if they are not correctly placed or printed, it can result in scanning errors and create logistical issues.

How to do

a) Use high-quality printing: Ensure that the barcodes or QR codes are printed using high-resolution printers that produce clear and legible codes. Faded or distorted codes can be challenging to scan accurately.

b) Size and scaling: Maintain the recommended size and scaling for the codes to ensure they can be scanned efficiently. Codes that are too small or too large may not be properly recognized by scanners, causing delays and errors in tracking.

c) Proper placement: Position the barcodes or QR codes on the packaging in a location that is easily accessible and visible. Avoid placing them near seams, folds, or other potential obstructions that could hinder scanning.

By implementing these practices, you can minimize the risk of incorrect barcodes or QR codes, streamline your inventory management processes, and prevent logistical challenges caused by scanning errors.

- Neglecting customer experience:

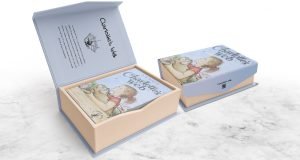

Packaging plays a crucial role in shaping the overall customer experience. Neglecting this aspect can result in missed opportunities to surprise and delight your customers.

How to do

a) Unboxing experience: Design your packaging in a way that creates a memorable unboxing experience. Use creative and attractive packaging designs, include tissue paper, ribbons, or other decorative elements to make the process exciting and enjoyable for customers.

b) Practicality and convenience: Make sure the packaging is practical and convenient for customers to use. Consider factors such as easy opening and resealing options, handles or grips for carrying, and appropriate sizing to fit storage spaces. This enhances usability and convenience for customers.

c) Surprise elements: Consider adding unexpected surprises within the packaging, such as small freebies, discount coupons for future purchases, or informative inserts that provide additional value. These surprises can leave a lasting impression and encourage repeat business.

d) Interactive Packaging: Consider incorporating interactive elements into your packaging to engage customers on a deeper level. This could include features such as peel-off stickers, hidden messages, or augmented reality experiences that create a memorable and immersive brand experience.

Remember, packaging is an extension of your brand and an opportunity to connect with customers on a deeper level. By prioritizing the customer experience and incorporating thoughtful elements into your packaging design, you can create positive and memorable interactions that build loyalty and advocacy.

- Ineffective Inserts or Filler Materials:

When packaging goods that consist of loose items, such as multiple products or accessories, it is crucial to use appropriate inserts or filler materials to secure them properly. This step is essential in preventing any movement or potential damage that may occur during the shipping process.

a) Bubble Wrap or Foam Cushioning: Utilize bubble wrap or foam cushioning to create a protective barrier around individual items. These materials provide shock absorption and prevent movement during transit, reducing the risk of damage.

b) Dividers or Partitions: If you have multiple items within the package, consider using dividers or partitions to create separate compartments for each item. This prevents them from coming into contact with each other and reduces the chances of scratches, dents, or other forms of damage.

c) Air Pillows or Packaging Peanuts: Air pillows or packaging peanuts can be used to fill empty spaces within the package. They act as a cushioning material and help immobilize the items, ensuring they remain in place during transportation.

d) Custom Inserts or Molded Packaging: For delicate or irregularly shaped items, consider using custom inserts or molded packaging. These inserts are designed specifically for the shape and size of the item, providing a secure fit and maximum protection.

By implementing these measures, you can significantly reduce the risk of damage caused by ineffective inserts or filler materials. Remember, providing adequate protection and stability for your goods is essential for maintaining customer satisfaction and minimizing potential losses during transit.

In the vibrant and diverse world of product business, packaging serves as a silent yet dynamic force that can determine your success. We have embarked on a journey, uncovering the 15 most common packaging mistakes in our industry, providing you with knowledge and guidance to avoid these pitfalls.

Take action now, integrate this crucial knowledge into your packaging strategy, and add attractiveness, protection, and sustainability to your products, allowing them to stand out in the market and win customers’ hearts.

Start today and let your packaging become the key to your product’s success!