As an e-commerce business owner, you know that poly mailers are a huge help every single day. They are not only affordable and lightweight, but they can also withstand practically any weather. A poly mailer will ensure that order stays dry and safe for longer lengths of time for forgetful customers to pick up their items in a timely manner. Poly mailers come in a variety of sizes and forms, so you may find the ideal fit for whatever it is you’re mailing. They also offer secure transportation without the weight of a box. They are also simple to store! Therefore the ideal poly mailer is your best option if you’re seeking a quick and easy approach to distributing goods or commodities.

But have you ever stopped to have a good look at the beautiful plastic envelopes and consider more about them? What materials are they made with? Are they good for the environment? How do these helpful products come into being? It’s time to take a look backstage and learn about the raw materials and production process behind the scenes!

No matter whether you are an e-commerce business owner or an avid online shopper, you are no stranger to poly mailers and most likely can’t live without them every day. Poly mailers, also known as mailer envelopes or poly mailer bags, are widely used in the logistics industry as packaging bags for documents, papers, various daily necessities, goods, etc. Poly mailers have the advantages of good waterproof protection and cost-effectiveness. With their self-sealing strip design, they also provide an easy assembly that saves you both time and labor costs.

Poly mailers are made from polyethylene. It’s a kind of durable plastic-based material that offers secure protection for items during transit to their destination. Basically there are two types of polyethylene, LDPE (low-density polyethylene) and HDPE (high-density polyethylene).

HDPE and LDPE both have their different benefits. Yet, the density is the key distinction between them. HDPE has a significantly higher density than LDPE. Non-toxic and rather brittle poly mailers made of HDPE make a louder sound when you pinch them. Moreover, it has a very tough texture that increases its tensile strength and resistance to tears and punctures. In comparison to its competitors, it can sustain greater pressures and has a higher melting point. However, this increased durability makes it less flexible compared to LDPE.

The density of LDPE is lower than HDPE. With a low melting point, LDPE is non-toxic, soft, not easily torn, and has high transparency. All these features make it incredibly flexible. It also has a soft sound and feel when you pinch it.

The answer is yes! Though the recycling process is not as simple, poly mailers are still an environmentally-friendly solution. A simple and accessible way is by visiting your local recycling center or grocery store which often includes a collection point for plastic sacks and poly mailers.

For the sake of environmental protection and to avoid waste, there are many countries that advocate adding a certain percentage of recycled material in the production of poly products. Recycled polyester offers almost the same quality as virgin materials but with significant energy savings. In 2017, research conducted by Switzerland’s Federal Office for Environment found the production of recycled polyester used 59% less energy than its virgin counterpart.

At Package N’ Go, we are dedicated to promoting green packaging practices. In the interest of environmental sustainability for future generations, our team is committed to reducing waste by avoiding producing poly mailers with 100% virgin materials wherever possible. We understand that it takes every effort from all of us to protect and preserve our planet!

Now you know what materials the poly mailers are made with. Let’s talk about how they come to our hands as beautiful plastic envelopes from insignificant small plastic particles. I’ll lead you around the production line.

The production process of ordinary poly mailers basically has four sections, blending, film blowing, printing, and bag making.

➼ Blending

The blending process is the key to the production of the poly mailer. Different countries have different environmental standards, and customers have their own requirements and preferences, which need to be implemented in the blending process. For this reason, it is important to use a mixer to add the required raw materials (master batches as well as new and recycled plastic pellets, etc.) in the right proportions and to mix them well. Only through careful and professional handling can we produce first-class products and win the approval of our customers.

➼ Film Blowing

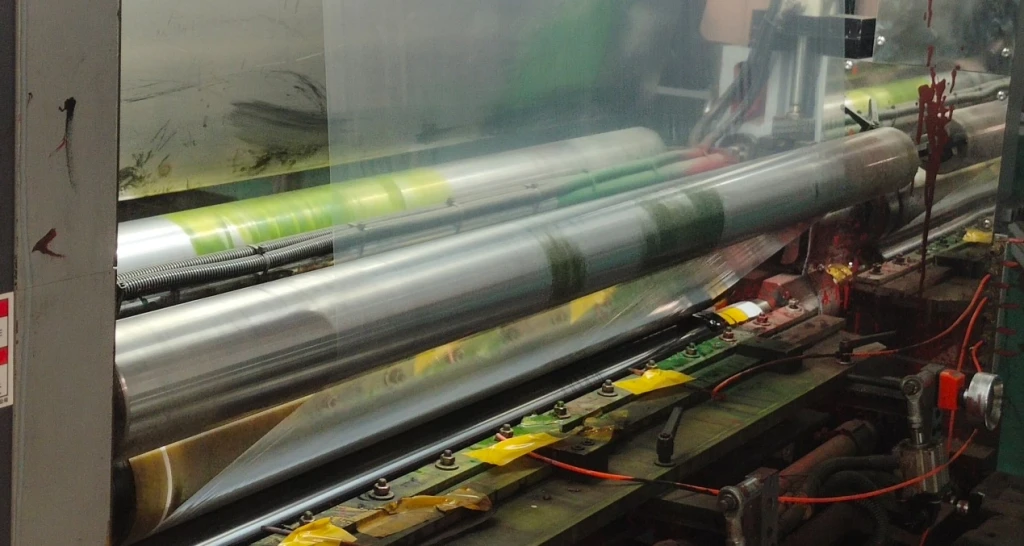

Film blowing is a plastic processing method that refers to heating and melting plastic particles and then blowing them into a film. It firstly extrudes polymer into a tubular film blank, then blows the tubular film to the required thickness by high-pressure air in a good melt flow state, and then after a process of cooling and shaping, the film is made. In the production of film, the film-blowing machine is essential. A variety of high-grade film packaging can be made with the film created by a skilled and sophisticated film-blowing equipment. Because of its strong barrier, freshness, moisture-proof, frost-proof, oxygen barrier, and oil resistance, this type of film can be widely utilized for both light and heavy packaging products. If the film produced is of low quality, it’s either because a non-professional film-blowing machine is used or the operation specifications and procedures were not strictly followed.

The poly mailers we use are usually laminated by three layers of film, and such a film is called three layers of co-extruded film. Compared to many goods in the market today, this kind of film has the advantages of good transparency, good puncture resistance, suitable coefficient of friction, good laminating properties, and excellent heat adhesion and anti-pollution heat sealing properties. The inner layer of poly mailer is usually black or gray to promote confidentiality during transportation and the outer layer is light gray, but of course, you can design poly mailers and customize them according to your requirements.

➼ Printing

Poly mailer bags are usually printed using a gravure press. First, an etched plate with the desired poly mailer design or text is printed on a copper plate by means of a gravure printing technique. This specialized technique ensures that the ink is used only on the designed area and not on any unwanted parts so that blurring and smudging does not occur. The plate with ink attached and the three layers of co-extruded film are fully extruded to complete the printing.

As a customer, you can personalize your poly mailer with patterns and texts. You can choose either full-plate printing or partial printing, and the colors can be single or multi-colors. But of course, only experienced printers and advanced high-precision presses can fulfill such printing needs with high quality. Due to the flexibility of the polystyrene material, if substandard machines are used or the workers lack experience in operation, it is likely to lead to uneven printing or overprinting, etc. which could influence on the printing results.

➼ Bag Making

After checking the printings, we will enter the last step of the production line of the poly mailer bag – bag cutting and bag making. In this step, three layers of the co-extruded film are first laminated with the hot melt adhesive, and then it’s cut and heat sealed precisely by the knife head of the bag-making machine. Now the poly mailer envelope is produced. Qualified hot melt adhesive has the characteristics of good initial adhesion, strong holding force, oil seepage resistance, etc. Once bonded, it can not be torn, so as to achieve the anti-counterfeiting and anti-theft function of the poly mailer. Therefore, the choice of hot melt adhesive in the bag-making process is also very critical.

With a detailed understanding of the raw materials and production process of the poly mailer, we are sure this will help you in the selection and purchase of packaging products.

Package N’ Go Productions offers a range of services to help businesses maximize the potential of their e-commerce platform. Our extensive global network enables us to provide our clients with cutting-edge solutions for custom packaging, fulfillment, and distribution needs around the world. We strive to support companies in realizing their ideas through interactive package design processes that are highly effective yet eco-friendly.

Make sure you explore our extensive selection of shipping solutions so that your products arrive safely and securely. Plus, don’t forget to take advantage of our industry-leading expertise – we’re here to help if you need advice on packaging or personalization options.