Table of Contents

Chapter 1: Understanding tear open boxes

1.1 What is a tear open box?

Tear open boxes, also known as tear strip boxes or pull-tab boxes, are a type of packaging designed for easy opening. They feature a tear-off strip or perforated section that allows consumers to open the box without the need for scissors or other tools. This innovative design simplifies the unboxing experience and enhances user convenience. This type of box also has anti-theft and anti-snooping features. Once opened, it cannot be restored.

1.2 What are the uses of tear open boxes?

The tear open box plays a crucial role in transportation. Its sturdy structure and appropriate size make it an ideal choice for shipping a variety of goods and items.

In storage, the tear-open box also plays an important role. Its simple design makes it very practical for temporary or long-term storage, suitable for various occasions and environments. Tear open boxes are easy to stack, saving storage space, and they also feature moisture resistance, dust protection, or insect prevention, ensuring that stored items remain clean and safe.

The tear open box not only serves a purpose in transportation and storage but also has unique advantages in product display. Its stylish and simple appearance attracts customer attention, making it a highlight of product displays. Transparent or beautifully printed tear open boxes can showcase the appearance and features of the internal products, enhancing their appeal. Additionally, tear open boxes can be used to display multiple products in stores or exhibitions, making product displays more neat and organized.

1.3 Common sizes

Here are some common size options for various items, which you can choose based on your specific needs. If you’re uncertain about the right size for your products, don’t hesitate to contact us for assistance.

9.2×9.2×5cm (3.6×3.6×1.97inch): These boxes are perfect for jewelry, cosmetics, or small accessories, adding value to your products.

11.8×14×8cm (4.65×5.51×3.15inch): Another option suitable for jewelry, cosmetics, and small accessories, providing a slightly larger dimension for your products.

32×18.9×9cm (12.6×7.5×3.6inch) and 30.2×23.3×8.8cm (11.9×9.2×3.5inch): These medium-sized boxes are highly popular for clothing items such as T-shirts, dresses, blouses, trousers, and light jackets, ensuring an ideal fit.

35×26×10cm (15×10.2×3.9inch): A larger size option for medium-sized clothing items and other products.

44×33.9×15.9cm (17.3×13.3×6.3inch) and 42.5×52×18cm (16.7×20.5×7.1): For larger electronic appliances or heavy clothing items, our spacious tear open boxes offer the perfect match.

Remember, we also offer customization options, allowing you to tailor the size to your specific requirements. Feel free to reach out to us to discuss your unique packaging needs and preferences.

1.4 What are the benefits of tear open boxes?

Tear open boxes offer numerous advantages for both businesses and consumers.

User-friendly design: The primary advantage of tear open boxes is their user-friendly design. The tear-off strip or perforated section allows for easy and quick opening without the need for scissors or sharp objects. This simplicity enhances the unboxing experience for consumers.

Convenience: Tear open boxes are incredibly convenient for consumers, as they can access the contents effortlessly. This is particularly valuable in today’s fast-paced world where consumers appreciate time-saving solutions.

Brand visibility: Tear open boxes provide ample space for branding and visual appeal. Companies can use this space to display their logos, product information, and marketing messages prominently, increasing brand recognition.

Customization: Tear open boxes come in various sizes, materials, shapes, and styles, allowing businesses to customize their packaging to suit their products and brand identity. This flexibility makes it easy to create unique and eye-catching designs.

Sustainability: Many tear open boxes can be produced using eco-friendly materials, contributing to sustainable packaging practices. This is increasingly important as consumers become more environmentally conscious.

Retail presentation: Tear open boxes are ideal for retail environments because they can be displayed attractively on store shelves. Their visual appeal can help products stand out and attract customers.

E-commerce ready: Tear open boxes are well-suited for e-commerce packaging. They provide both protection and convenience for products being shipped to customers, enhancing the online shopping experience.

Versatility: Tear open boxes can be used to package a wide range of products, from snacks and cosmetics to electronics and pharmaceuticals. Their versatility makes them a popular choice across various industries.

Unboxing experience: The tear open box’s unique opening mechanism creates an enjoyable unboxing experience for consumers. This can lead to positive reviews, social media sharing, and increased customer loyalty.

Tamper-evident features: Tear open boxes can incorporate tamper-evident seals or closures, ensuring that the product has not been tampered with before reaching the consumer.

Cost-efficiency: These boxes can often be produced cost-effectively, making them an attractive packaging option for businesses looking to balance quality and budget. While adding a more convenient feature, tear-open boxes do not incur significant additional production costs.

Chapter 2: Eco-friendliness of tear open boxes

In recent years, the global concern for environmental issues has prompted a reevaluation of packaging materials and their impact on the planet. Tear open boxes have gained popularity due to their convenience and functionality, but how do they stack up in terms of eco-friendliness?

2.1 Are tear open boxes recyclable?

Compared with plastic packaging, tear open boxes, which are paper based, are a much more eco-friendly option, as paper is taken from nature, and will be returned to nature. And it’s biodegradable and compostable. But before it goes back to nature, it can also be recycled for several times.

Paper based tear open boxes are generally recyclable, but if it features with plastic tear strip, this part shall be recycled seperatly. Also, post-press coatings such as UV or foil stamping can also complicate recycling processes.

So it’s essential for manufacturers and consumers to be aware of the recycling guidelines in their region and make informed decisions regarding the disposal of packaging. Additionally, efforts should be made to design tear open boxes with easily separable components, making recycling more efficient.

2.2 Tear open boxes made of recycled materials

One of our promising steps toward eco-friendliness is the use of recycled materials in the production of tear open boxes. By incorporating post-consumer recycled materials,we can reduce the demand for virgin resources and minimize the environmental impact of production.

The use of recycled materials not only conserves resources but also reduces energy consumption and greenhouse gas emissions associated with manufacturing.

2.3 Certifications from authorities

Certifications from environmental authorities play a pivotal role in assessing the eco-friendliness of packaging materials. Organizations such as the Forest Stewardship Council (FSC) and the Sustainable Forestry Initiative (SFI) provide certifications for sustainable sourcing and responsible forest management. Tear open boxes that carry these certifications can be considered more environmentally friendly.

With China’s development, our material suppliers are all excellent manufacturers with relevant qualifications and certifications (such as FSC, RoHS), supporting us in providing customers with more reassuring products.

Chapter 3: Customization of tear open boxes

3.1 Types of tear open boxes

3.1.1 Classified by materials

Tear-open boxes can be classified based on the materials used to make them. The two common categories are paperboard tear-open boxes and cardboard tear-open boxes.

3.1.1.1 Paperboard tear open boxes

Paperboard Tear-Open Boxes are a popular choice for packaging a wide range of products that require a balance between protection and affordability. These boxes are typically crafted from a thicker and more rigid type of paperboard material, ensuring they maintain their shape and provide adequate safeguarding for their contents. The selection of the appropriate type of paperboard depends on factors such as aesthetics, functionality, and product requirements. Common types of paperboard used for making tear-open boxes include:

CCNB (Clay coated news back): CCNB is a paperboard material with a clay-coated side that offers excellent printing quality. The grammage of CCNB cardboard typically ranges from 250g to 400g. It is commonly used for tear-open boxes where vibrant graphics or branding are essential.

SBS (Solid bleached sulfate): SBS is a premium-grade paperboard known for its smooth and glossy surface. The grammage typically ranges from 230g to 400g. It provides a high-end look and is often used for luxury product packaging.

C2S (Coated two sides): C2S paperboard features a coating on both sides, making it versatile for printing and suitable for tear-open boxes that require a polished appearance. The grammage typically ranges from 300g to 400g.

Natural brown kraft: Natural brown kraft paperboard is unbleached and has a rustic, eco-friendly appearance. It is often chosen for tear-open boxes aiming for a more organic and environmentally-conscious image. The grammage typically ranges from 200g to 350g.

White kraft: White kraft paperboard offers a clean and crisp look, making it suitable for a variety of products, especially those with a minimalist or sophisticated design. The grammage typically ranges from 200g to 350g.

Black kraft: Black kraft paperboard provides a unique and elegant option for tear-open boxes, often selected for high-end or fashion-oriented items. The grammage typically ranges from 200g to 350g.

Specialty paper: Specialty paperboards encompass a wide range of options, including textured, metallic, or patterned surfaces, which can be chosen to create customized and distinctive tear-open box designs. The grammage typically ranges from 200g to 350g.

The thickness of cardboard used for making tear open boxes typically ranges from 0.2mm to 0.6mm, depending on the characteristics of the packaged product. The choice of thickness ensures that the material is sufficiently sturdy to maintain shape and protect contents while still being easy to fold and open. The selection of cardboard weight depends on the specific requirements of the packaged product, including its weight, fragility, and the level of protection needed during handling and transportation.

3.1.1.2 Cardboard tear open boxes

Cardboard is a thicker and more durable material compared to paperboard. It exhibits a three-layer composition, encompassing an inner fluted layer embraced by two flat linerboards.

Cardboard tear-open boxes are commonly used for packaging heavier or bulkier items that require extra strength and protection during shipping and handling. These boxes are often used for packaging electronics, appliances, automotive parts, and other products that need robust packaging.

Linerboard options:

Kraft linerboard: Kraft linerboard is made from new materials or 100% recycled materials and boasts a classic brown appearance. It’s an excellent choice for promoting organic or eco-friendly products. However, it’s important to note that bright colors printed on kraft may appear more subdued due to the natural paper color.

Premium white linerboard (CCNB/SBS): Premium white linerboard is known for its delicate coating, which imparts heightened brightness and glossiness. It is ideal for showcasing vibrant full-color designs, ensuring that a diverse and bold color palette stands out impressively.

Medium corrugated sheet:

Corrugated sheets offer options with single fluted layers and double fluted layers. When crafting common tear-open boxes, it is recommended to use a single fluted layer. Excessively thick corrugated sheets can hinder folding and assembly, impacting packaging efficiency. Commonly used corrugated types for tear-open boxes include:

B-flute: Provides good strength and crush resistance. Suitable for various applications.

C-flute: Offers higher stacking strength and cushioning. Ideal for protecting fragile items.

E、F/N-flute: Known for its thin profile and excellent printability. Suited for packaging with intricate designs.

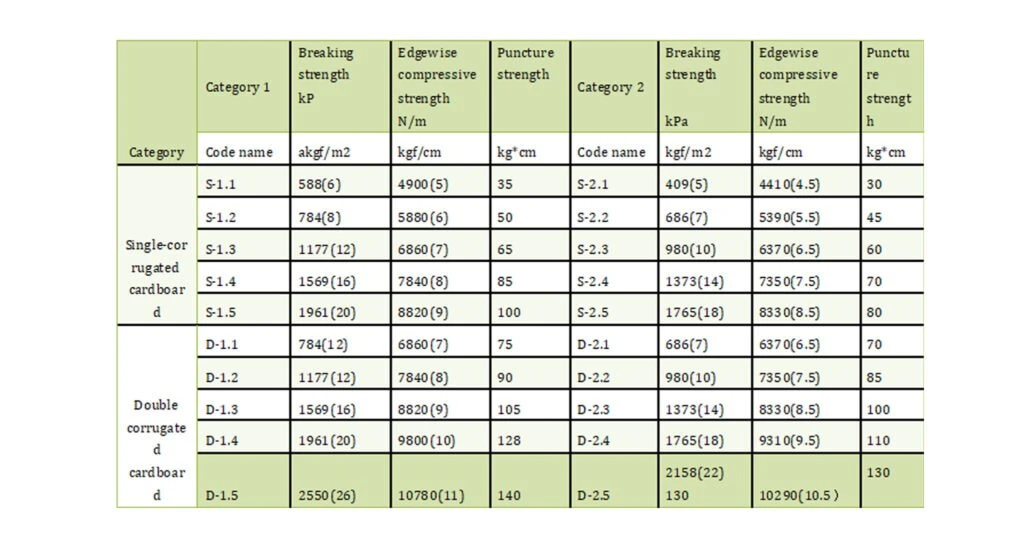

Designing tear open boxes for transportation purposes, it is recommended to use double-layer corrugated cardboard. Common combinations include F/E flute, E/B flute, E/C flute, and B/C flute. The choice of corrugated cardboard thickness should be based on the fragility and weight of the packaged product. The outer linerboard of double-layer corrugated cardboard can also be paired with different materials (see details in cardboard selection). Below are the performance parameters of corrugated cardboard.

S – Single corrugated cardboard (three-layer corrugated cardboard)

S-1.1 ~ S-1.5 – respectively the first class to fifth class of single corrugated cardboard premium grades;

S-2.1 ~ S-2.5 – respectively the first class to fifth class of single corrugated cardboard qualified grades;

D – Double corrugated cardboard (five-layer corrugated cardboard)

D-1.1 ~ D-1.5 – respectively the first class to fifth class of double corrugated cardboard premium grades;

D-2.1 ~ D-2.5 – respectively the first class to fifth class of double corrugated cardboard qualified grades;

T-1.1 ~ T-1.4 – respectively the first class to fourth class of triple corrugated cardboard premium grades;

T-2.1 ~ T-2.4 – respectively the first class to fourth class of triple corrugated cardboard qualified grades.

3.1.2 Classified by structures

Mailer box: Mailer boxes are designed for easy assembly and secure closure, making them ideal for shipping and e-commerce packaging. They often have a tear strip for easy opening. These boxes are suitable for shipping various products such as clothing, books, cosmetics, and smaller electronic devices.

Display box: Display boxes are designed to showcase products on store shelves even after opening. They usually have a front flap that can be opened and reclosed. These boxes are great for retail packaging of items like chocolates, toys, cosmetics, and electronics.

Flap box: Flap boxes are characterized by their flaps that fold over to close the box. They can have a tear-open feature for convenient access. Flap boxes are versatile and can be used for packaging a wide range of items, including apparel, accessories, and small household goods.

Truck box: Truck boxes have a unique shape resembling a truck or a vehicle. They are often used for promotional packaging and can have a tear-open feature for added convenience. These boxes are great for packaging toy cars, promotional merchandise, or novelty items.

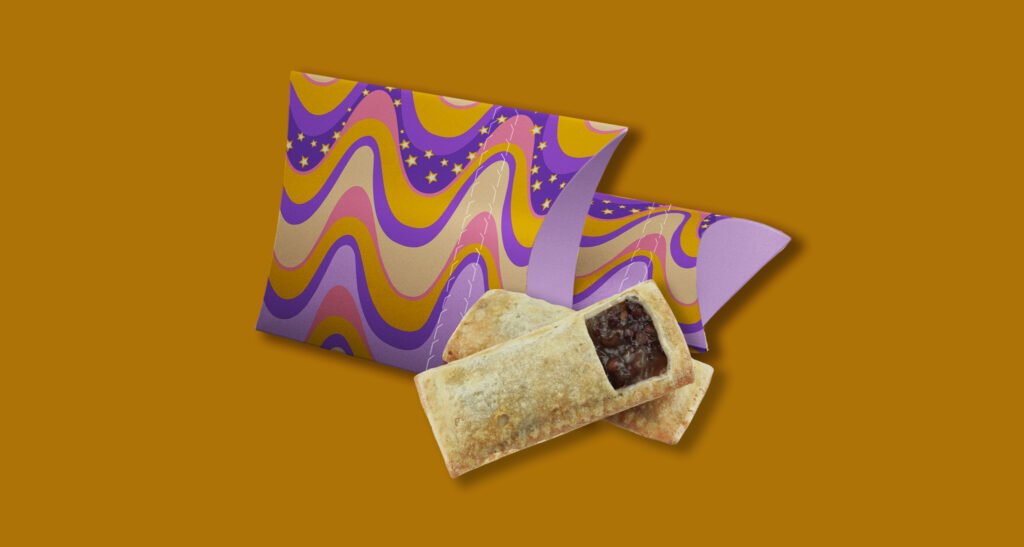

Pillow box: Pillow boxes have a curved shape, resembling a pillow. They are easy to assemble and often have a tear strip for opening. Pillow boxes are ideal for packaging small gifts, jewelry, party favors, and cosmetics.

Book style box: Book style boxes have a hinged lid and open like a book. They provide a luxurious and elegant packaging solution. These boxes can be equipped with a tear-open feature for added functionality. Book style boxes are commonly used for packaging high-end items like watches, jewelry, and luxury clothing.

Sleeve box: Sleeve boxes consist of a sliding outer sleeve and an inner tray. They can have a tear strip for easy access to the contents. Sleeve boxes are suitable for products that require a premium presentation, such as perfumes, candles, and gourmet chocolates.

Gable box: Gable boxes have a unique shape with a built-in handle, making them convenient for carrying. They can also include a tear strip for opening. Gable boxes are often used for packaging food items, party favors, and gift items.

Drawer box: Drawer boxes have a sliding drawer that can be pulled out from a sturdy outer sleeve. They can include a tear strip for easy access. Drawer boxes are suitable for packaging luxury items, electronics, and gift sets.

These tear-open box types offer a variety of options for packaging different products while providing convenience and functionality to both retailers and customers. The choice of box type should align with the specific product’s size, shape, and packaging requirements.

3.2 Tear strips

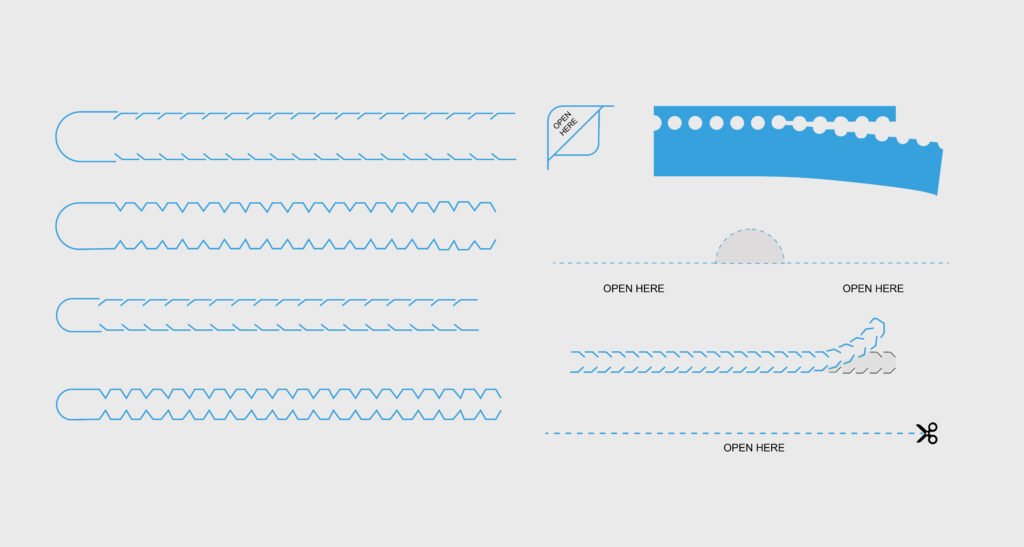

Tear strips on tear-open boxes come in various types, each designed to provide a specific opening mechanism or user experience. Here are 2 common types of tear strips used on tear-open boxes:

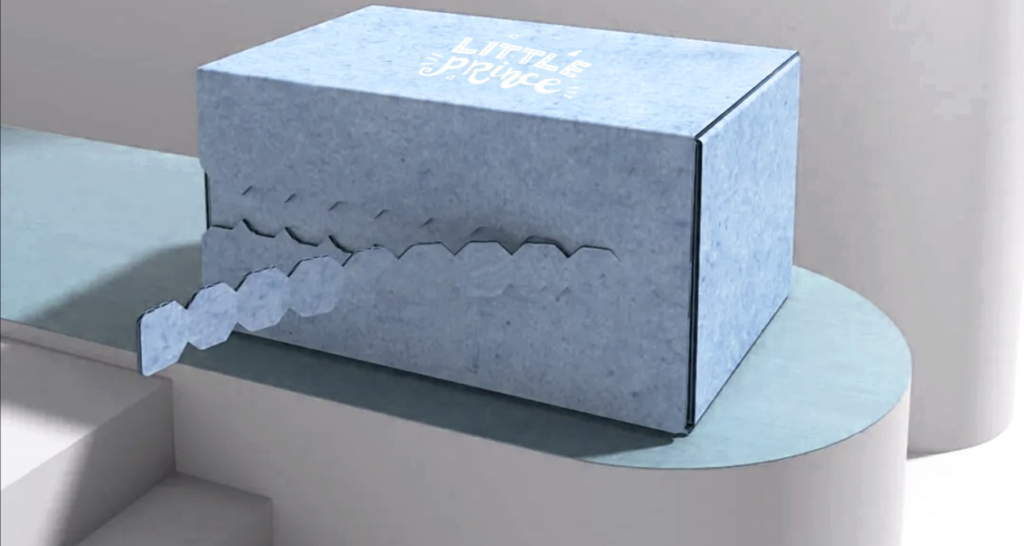

3.2.1 Die-cut tear strip

Die-cut tear strips are engineered with precision, featuring a specialized cut or groove in the packaging material that facilitates easy tearing along a predefined path. These tear strips are employed on a wide range of packaging solutions, including boxes for electronics, toys, and household goods. The die-cut design ensures that users can effortlessly follow the intended tear line, making the opening process intuitive and user-friendly. This type of tear strip enhances the overall unboxing experience, ensuring that consumers can access the product inside with ease.

3.2.2 Pull tab tear strip

Pull tab tear strips are characterized by a small, user-friendly tab or extension typically made from durable PVC material. Users can easily grip and pull this tab to initiate the tearing process. These tear strips are frequently employed on packaging for items like snacks, beverage cartons, and resealable pouches. The PVC pull tab provides a secure and comfortable grip, allowing consumers to open the packaging without the need for additional tools. It ensures quick and convenient access to the contents while maintaining the integrity of the package. This tear strip design is particularly well-suited for products that require repeated access and resealing, making it a popular choice for resealable packaging solutions.

Tear strips may seem simple, but they require a high level of skill from machine operators during actual production. We aim for tear strips to cleanly and sharply tear off while ensuring they do not tear open due to external forces during transportation. Typically, we have machine operators adjust the machines while conducting tear tests to achieve an ideal balance.

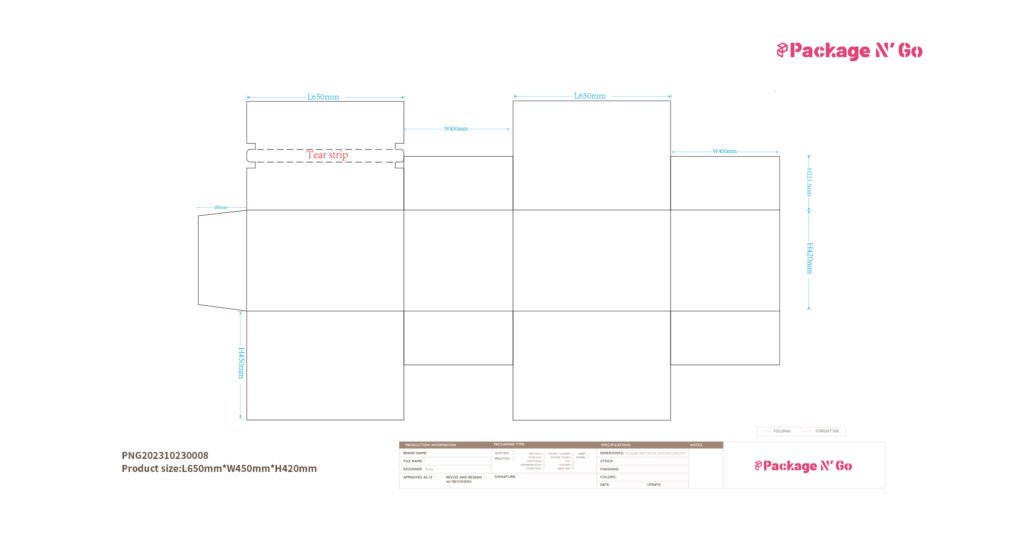

3.3 What design files should be provided

File format: Please provide artwork in AI (Adobe Illustrator) or PDF format to ensure high-resolution quality.

Resolution: Ensure that the artwork has a minimum resolution of 300 DPI (dots per inch) to guarantee sharp and clear prints.

Color mode: Use CMYK color mode for optimal four-color process printing. Avoid RGB mode to prevent any color printing issues.

Fonts: Convert all text to outlines or include the specific fonts used to prevent font replacement problems.

Graphic elements: All logos, photos, and icons should be of high quality and accurately positioned. Ensure proper attribution and avoid the use of copyrighted images without permission.

Bleed area: Include an additional 3 to 5 mm around the edges to accommodate bleed, ensuring that there are no white margins after cutting and printing.

3.4 Postpress enhancements

For an added touch of elegance and sophistication, consider incorporating post-press enhancements into your tear open boxes. Options such as spot UV coating, foil stamping, embossing, or glitter accents can elevate the visual appeal of your packaging, making it truly eye-catching and memorable.

Post-printing enhancement techniques often achieve more unique colors, glossiness, textures (such as UV coating, hot stamping, glitter, holographic effects, etc.), and even three-dimensional embossing effects on flat surfaces (through embossing, debossing, screen printing, etc.). Laminating can enhance the visual appeal and protect the printed surface. What’s even better is that these techniques can be combined on the same packaging, allowing designers more freedom, boldness, and precision in their ideas. However, it’s best to have the assistance of professional craftsmen for the optimal combination.

3.4.1 Spot UV

Enhance your packaging with spot UV, an impressive post-press technique that imparts a glossy shine to selected elements like your company logo and printed images. This not only improves the overall aesthetics of your packaging but also infuses it with a touch of refinement. The modern and elegant finish sets your product apart on store shelves and captivates your audience, making your brand truly shine.

UV (Ultraviolet) is a surface treatment technique for printed materials. The basic principle involves using high-temperature ultraviolet light to quickly dry UV ink and adhere it to the surface of paper. Different UV inks can be selected to achieve various colors and glossy effects. Additionally, different sizes of areas can be UV-treated, such as full-sheet or partial UV. The quality assessment of UV effects typically focuses on two key points: the UV surface must be flat to achieve a mirror-like effect, and the UV curing must be good to ensure the surface does not blur or peel under pressure and wear.

3.4.2 Foil Stamping

Delve into the intricate art of foil stamping to imbue your items with texture, luminosity, and captivating aesthetics. Foil stamping offers a range of choices, including metallic, pigment, or holographic foil, each contributing a unique and enchanting effect that elevates your packaging’s allure. Beyond its visual appeal, foil stamping is remarkably durable, enduring variable climates and the test of time, ensuring your packaging radiates enduring brilliance over extended periods. Because foil stamping consumables contain real metal materials such as aluminum, they exhibit a metallic luster and texture that other technologies currently cannot replicate.

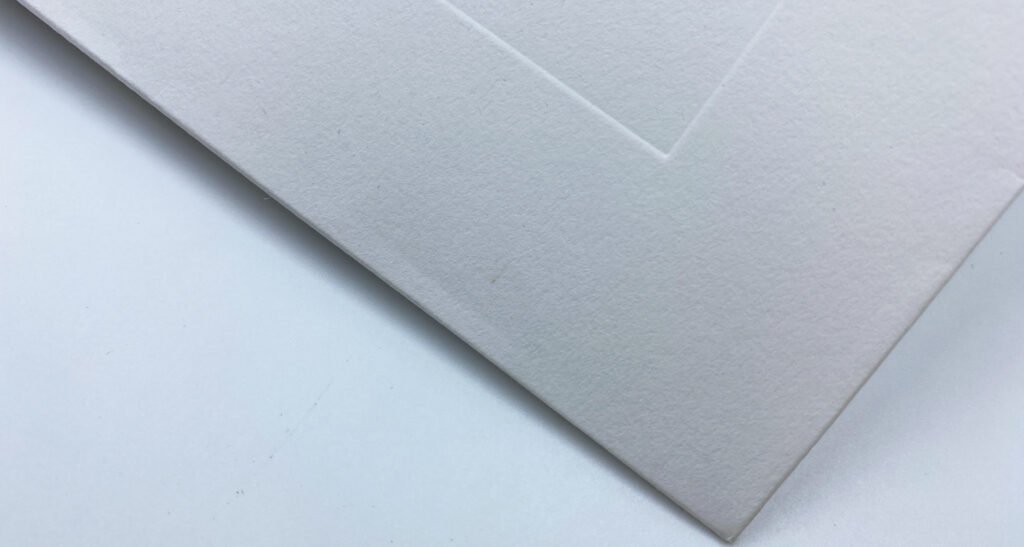

3.4.3 Embossing & Debossing

Craft a visual and tactile masterpiece with embossing and debossing. Embossing raises elements on your packaging, drawing attention and setting your product apart. Conversely, debossing adds a recessed texture, offering a unique tactile experience. In a competitive packaging market, these techniques help your brand stand out and add a touch of style and texture to otherwise flat surfaces.

This technique adds a three-dimensional effect to flat printing surfaces, bringing about a dual change in both visual and tactile perception. By incorporating high-resolution effects like embossing, shading, and textured finishes in our designs, we can achieve a realistic and lifelike appearance using this method.

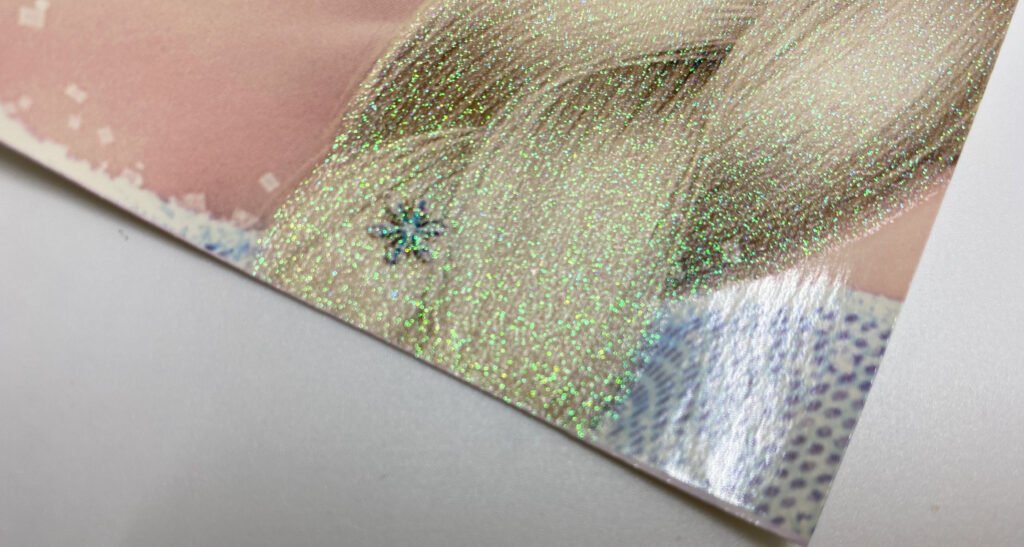

3.4.4 Glitter Printing

Infuse your products with dazzling sparkle and shine through glitter printing. This special technique transforms your packaging into an eye-catching masterpiece, perfect for standing out on store shelves. From jewelry containers to cosmetic cases, glitter printing adds a touch of prestige and enthralls your customers, leaving a lasting impression. Tailor your design to showcase your product’s best features and instantly captivate your audience.

3.5 Other creative design elements

Printing your brand’s logo and elements on tear-open boxes is crucial for brand recognition, professionalism, and marketing. Tear-open boxes can be printed with vibrant single-color, four-color, multi-color, or single-spot colors, making your brand stand out in a competitive market, fostering trust, and conveying essential product information. It enhances memorability, encourages repeat purchases, tells your brand story, creates a high-end image, strengthens online presence, and ensures compliance with regulations.

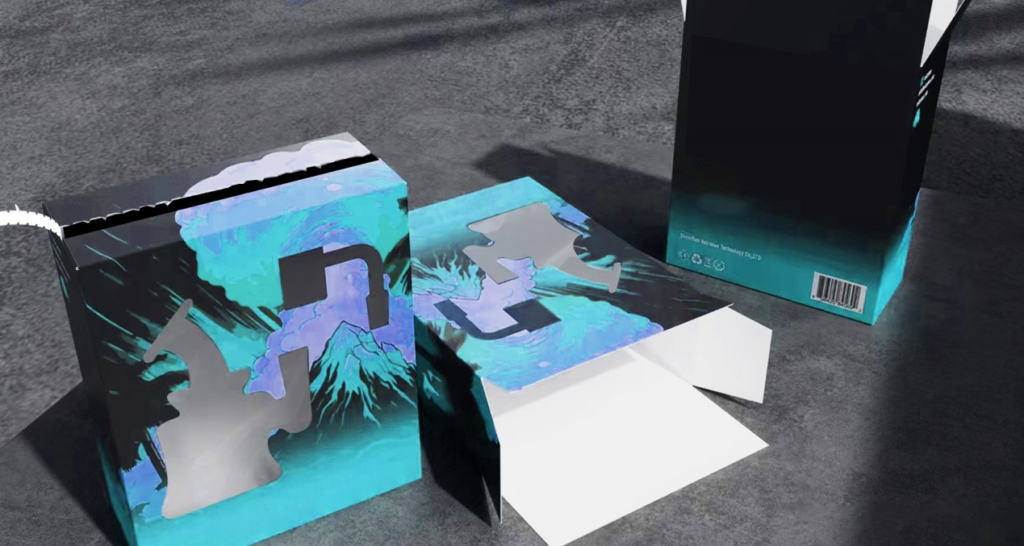

To create an unparalleled unboxing experience, we introduce a series of innovative design elements, elevating your tear-open boxes to an artistic level.

Window patch: Offer a tantalizing glimpse inside, sparking excitement and anticipation as recipients catch a sneak peek of their eagerly awaited treasures.

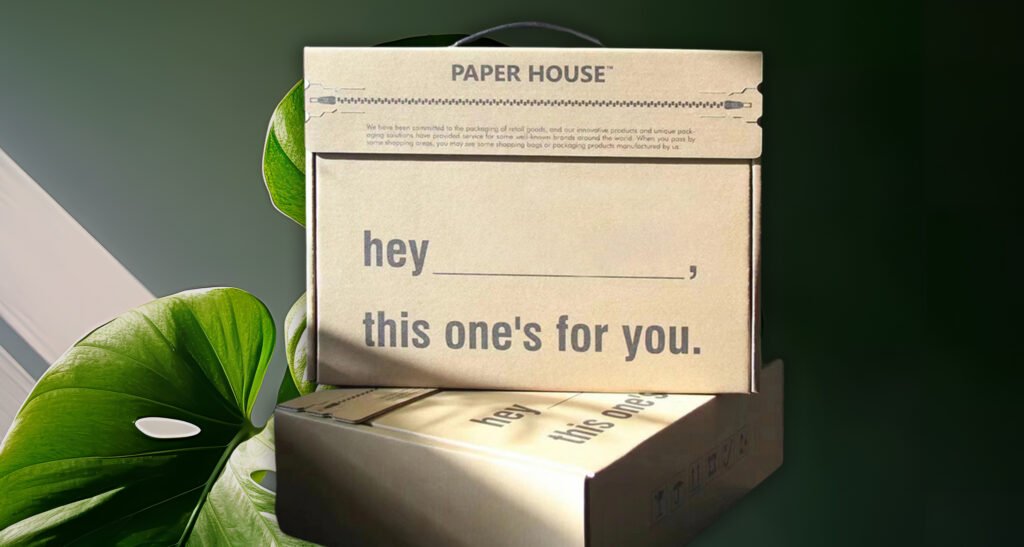

Zippers: Seamlessly blend functionality with aesthetics by integrating zippers. These not only provide effortless access to contents but also ensure items remain secure during transit.

QR codes: Forge a connection between the physical and digital worlds by incorporating QR codes. These codes enable interactive experiences that link customers directly to your brand’s online presence, adding a new dimension to the unboxing process.

Handle: Infuse practical elegance into your packaging. Incorporate handles that enhance portability and aesthetic appeal, ensuring your mailer boxes are easy to carry while exuding sophistication.

Sleeves: Elevate visual allure while bolstering protection with sleeves that envelop your mailer boxes. This extra layer not only adds an element of safeguarding but also provides additional branding opportunities to captivate your audience.

Chapter 4: How much are tear open boxes?

4.1 Prices of tear-open boxes

Whether you choose paperboard boxes or cardboard boxes, the decision to incorporate a tear strip, whether it’s a precision die-cut or a user-friendly plastic pull tab, offers a cost-effective advantage. This addition not only enhances the functionality of your packaging but also does so without significantly impacting your budget.

Tear-open boxes strike an ideal balance between affordability and user convenience, making them an increasingly popular choice in the packaging industry. By providing an easy and efficient means of accessing the contents, tear strips add value to your product while keeping production costs in check, making them a smart and budget-friendly packaging solution for businesses of all sizes.

4.2 Factors that influence prices

Materials:

The type of material used for your tear-open boxes is a key price influencer, for example:

SBS (Solid Bleached Sulfate) vs. CCNB (Clay Coated News Back): SBS tends to be more expensive compared to CCNB. CCNB is a common choice for cost-effective tear-open boxes.

Specialty Paper vs. Non-specialty Paper: Specialty paper, which includes unique textures or finishes, often comes at a higher price point compared to standard paper options.

Corrugated Sheets: Incorporating corrugated sheets into your boxes will increase production costs due to the added material and complexity.

Box size and style:

The size and style of the tear-open box play a significant role in determining its price. Larger boxes require more materials and labor, making them more expensive. Additionally, complex box styles, such as those with intricate folds or custom die-cut shapes, can increase production costs.

Printing and branding:

Custom printing, logos, and branding elements on your tear-open boxes can have a considerable impact on the price. Options like full-color printing, embossing, foil stamping, or the use of specialty inks add to the cost. Simpler one-color designs are typically more budget-friendly.

Quantity ordered:

The quantity of tear-open boxes ordered is also a critical factor affecting the price. Economies of scale come into play with larger order quantities. Ordering in bulk often results in lower unit prices, reducing the overall cost per box. Conversely, smaller orders tend to be more expensive on a per-unit basis.

Customization and complexity:

The level of customization and complexity in the design of your tear-open boxes can increase costs. Features like custom inserts, window cutouts, or unique closures add to the overall price but can enhance the presentation and customer experience.

Chapter 5: How are tear open boxes made

5.1 Printing

The initial phase in manufacturing tear-open boxes is the printing process. We utilize flexography printing for kraft paperboard and offset printing for white paperboard. These advanced printing techniques, combined with state-of-the-art technology and equipment, guarantee that your design is presented with vibrant colors and sharp details.

We take color accuracy seriously and, to achieve the perfect result, we perform multiple rounds of color calibration and adjustments during the pre-production stage. This meticulous process ensures that your boxes will flawlessly showcase your brand identity and design in a striking and precise manner.

Moreover, if you desire specific visual enhancements such as spot UV coating, glitter, or foil stamping, we meticulously apply these finishing touches after the printing phase to add an elegant and sophisticated touch to your packaging.

5.2 Composite (For corrugated boxes)

For corrugated cardboard boxes, an additional compositing step is essential. We combine two pieces of brown or white cardboard with a corrugated sheet, using a robust adhesive to create a single, durable piece. This composite is then flattened under heavy pressure to prevent bending and deformation.

The composited cardboard undergoes a natural drying process for about two days to enhance cohesion between the materials.

Mounting is a common adhesive operation in paper packaging, typically involving corrugated mounting and paperboard mounting. Through mounting, we can combine various printed materials together, greatly enriching packaging design and structural diversity. While mounting is proficient and stable in conventional cartons and colorful boxes, it poses a challenge in fine mounting packaging. We often need to ensure stability and reliability of mounting under various temperatures and humidities, avoiding detachment, bubbling, wrinkling, or glue overflow. Fortunately, we have a mature team and rich experience, making everything proceed smoothly.

5.3 Die-cutting

Die-cutting is a critical step that significantly influences the appearance and functionality of tear-open boxes. Custom shapes are precisely cut out using a die, which includes sharp blades for cutting edges and blunt blades for creases. If you opt for a tear line, it’s also achieved during this process.

Before mass production, our skilled technicians conduct multiple sampling inspections to ensure that the die’s pressure is precisely calibrated. This prevents the cardboard from being overly pierced, minimizing waste. Our experts thoroughly test each step to ensure that every box is manufactured to perfection.

To maintain the highest quality standards, our machines are regularly cleaned, guaranteeing that the finished products are free from defects like rough edges. Your tear-open boxes will be flawlessly crafted to meet your specifications and exceed your expectations.

5.4 Box cutting

The penultimate step involves giving shape to the boxes by removing offcuts. While this step may seem straightforward, it requires expertise, as it directly impacts the quality of the final product. We employ specialized equipment for this purpose.

5.4 Box gluing

The final step is box gluing, which is executed with the help of professional equipment. If you’ve chosen a pull tab tear strip, it is also integrated during this step. The result is a completed tear-open box, ready to impress.

Chapter 6: Package N’ Go makes it possible

With over two decades of experience, Package N’ Go is your trusted source for high-quality tear-open boxes and packaging solutions. Our commitment to innovation and sustainability is reflected in our products. We understand the importance of packaging as a brand identity tool.

Choose Package N’ Go as your packaging partner and elevate your brand with convenient, functional, and aesthetic packaging. Contact us today, and let’s start a journey that leaves a lasting impression on your customers. Package N’ Go – where packaging is a statement of quality and excellence.