Table of Contents

1. Introduction to the Process

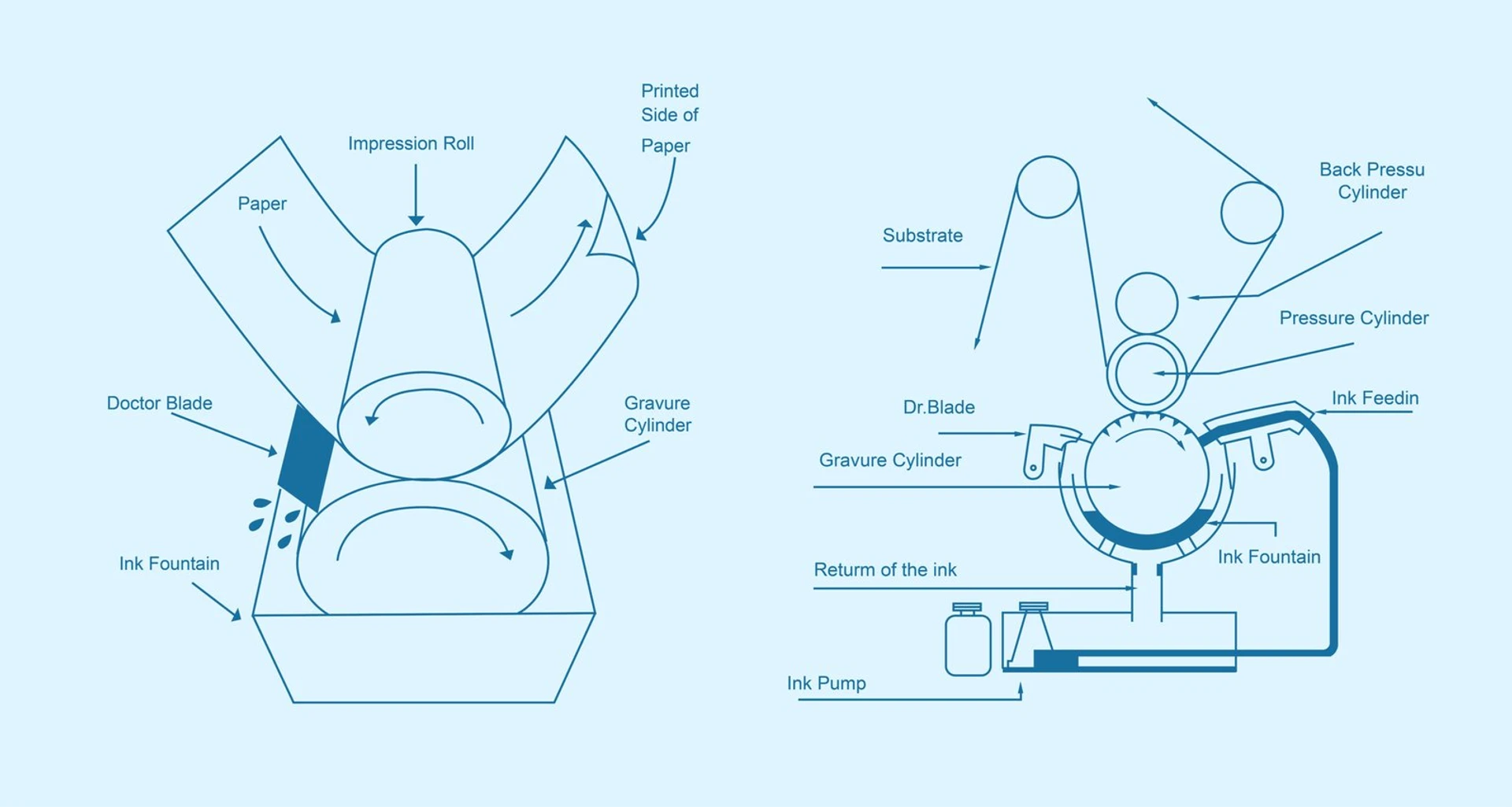

Gravure printing is a direct printing method where ink from the recessed cells of the gravure cylinder is transferred directly onto the substrate. In gravure printing, the image areas of the printing plate are below the surface of the plate, with varying depths corresponding to the tonal variations of the image. The non-image areas are raised and on the same plane. During printing, ink fills the recessed cells, excess ink on the surface of the plate is wiped away by a doctor blade, and the plate is then pressed onto the substrate with sufficient pressure to transfer the ink from the cells onto the substrate, completing the printing process.

2. Process Flow

The main steps of the gravure printing process include:

2.1 Design and Plate Making

Designing and creating the gravure printing plate according to the requirements of the print job. The plate must be precise, with clear details to accurately transfer the image.

2.2 Plate Making

Transferring the designed image onto the plate. Common methods include chemical etching, photomechanical processes, and mechanical engraving. The completed plate is inspected and refined to ensure quality and accuracy.

2.3 Printing Preparation

This includes adjusting the plate, setting up the printing press, mixing inks, and selecting the printing substrate, ensuring the smooth operation of the press.

2.4 Printing

Placing the prepared plate on the printing press, adjusting machine parameters, and beginning the printing process. During printing, temperature, humidity, and printing speed must be strictly controlled to ensure print quality.

2.5 Quality Inspection

Inspecting the printed materials for quality, including color, image clarity, and paper flatness, to ensure they meet the required standards.

2.6 Packaging and Shipping

Packaging the printed materials and shipping them according to customer requirements.

3. Characteristics of the Process

3.1 Image Areas Below Surface

The depth and size of the recessed cells determine the tonal variations of the image.

3.2 Clear Lines and Rich Details

Gravure prints are characterized by sharp lines, dense ink layers, and detailed, aesthetically pleasing images.

3.3 Complex Plate Making

Plate making is relatively difficult, with long cycles and high costs.

Overall, gravure printing, with its unique principles and process flow, holds a significant position in the printing and packaging industry.

4. Importance

Gravure printing demonstrates its importance in several fields:

4.1 High-Quality Printing

Produces high-resolution, high-quality prints due to its unique principle, ensuring precise ink transfer from recessed cells to the substrate.

4.2 Vibrant Colors and High Saturation

The thick ink layers result in vibrant, saturated colors, which is crucial in packaging and advertising to attract consumer attention and enhance product appeal.

4.3 Wide Range of Substrates

Suitable for various substrates including paper, plastic films, and aluminum foil, making it versatile in the packaging industry.

4.4 Strong Anti-Counterfeiting

Complex plate making makes reproduction difficult, offering strong anti-counterfeiting features, especially valuable in currency and securities printing.

4.5 Environmental Considerations

With increasing environmental awareness, gravure printing is continually improving its processes and materials to meet environmental standards, such as using water-based inks and solvent-free inks to reduce harmful emissions.

4.6 Adaptability

Can handle different batch sizes and requirements, whether for large-scale industrial production or small-batch custom jobs.

4.7 Economic Efficiency

Despite high plate making costs, the fast printing speed and high durability of the plates make it cost-effective for large-scale production.

In summary, gravure printing is essential for high-quality, vibrant, and secure prints across various substrates. With ongoing technological advancements, it continues to offer unique value and advantages in diverse fields.

5. Impact on Products

Gravure printing impacts products in the following ways:

5.1 Product Quality and Appearance

Vibrant Colors and Depth: Ensures vibrant colors and strong detail reproduction, providing high-quality prints with clear, rich images.

Thick Ink Layers: Creates dense, visually striking ink layers that attract consumer attention.

High Durability: The high durability of the printing plates allows for consistent quality in large print runs.

5.2 Production Efficiency and Costs

Fast Printing Speed: Automated production lines allow for rapid image transfer and printing, significantly boosting production efficiency.

Cost Reduction: Reusable plates and high-speed printing reduce material and unit production costs.

5.3 Special Effects and Customization

Special Effects: Can achieve various special effects like gloss, three-dimensionality, and holographic effects, adding artistic elements and enhancing visual appeal.

Customization: Capable of personalized customization to meet specific customer needs.

5.4 Wide Application Range

Used extensively in packaging, magazine and book printing, financial and insurance printing, and cosmetics and personal care product printing due to its high quality, versatility, and adaptability.

In conclusion, gravure printing significantly enhances product quality, production efficiency, and customization options, making it an ideal solution for various printing needs.

6. Common Issues and Solutions

6.1 Common issues

6.1.1 Slow Drying Speed

Symptoms: Causes roller contamination, adhesion issues, and high residual solvents.

Causes: Slow solvent drying, deep plate cells, insufficient drying capacity, and fast printing speeds.

6.1.2 Surface Bubbles

Symptoms: Presence of bubbles in the print, affecting the doctor blade’s effectiveness.

Causes: Properties of the ink (especially water-based ink) and defects in the ink circulation system.

6.1.3 Skinning

Symptoms: A dry layer forms on the surface of the ink in the ink tray, which can transfer to the cylinder.

Causes: Fast-drying ink and air leakage from the drying system.

6.1.4 Set-Off

Symptoms: Ink from one sheet transfers to the next sheet’s surface.

Causes: The ink layer from the previous print dissolves on the next print’s surface.

6.1.5 Moire Pattern

Symptoms: Ink transferred to the substrate forms a dot pattern, creating isolated spots.

Causes: Fast-drying or high-viscosity ink and wide screen angles during plate making.

6.1.6 Ink Migration

Symptoms: Ink transfers to non-image areas, creating uneven tones.

Causes: Deep plate cells, low ink viscosity, and low ink temperature.

6.1.7 Adhesion Issues

Symptoms: Ink layers stick to each other, causing ink stripping and print contamination.

Causes: Poor drying, increased ink softness due to high temperatures, and excessive winding tension.

6.2 Solutions

Slow Drying Speed

Use appropriately fast-drying solvents, combine fast-drying solvents with deeper plates, and adjust printing speed to match drying capacity.

Surface Bubbles

Add defoamers in moderation and improve the ink circulation system.

Skinning

Adjust ink drying speed, ensure balanced airflow in the drying system, and cover the ink tray to avoid exposure to air.

Set-Off

Use weaker solvents for subsequent ink layers and maintain appropriate printing speeds.

Moire Pattern

Use slower-drying solvents, check for air leaks in the drying system, and print with low-viscosity inks.

Ink Migration

Use fast-drying solvents, high-viscosity inks, adjust screen angles, and preheat ink if necessary.

Adhesion Issues

Fully utilize cooling rollers, store prints in cool conditions, manage winding tension, and consult ink manufacturers for appropriate measures.

These solutions are for reference and should be adjusted according to specific production conditions and printing requirements.

7. Application Examples

7.1 Example 1: Gravure Printing on Plastic Film Packaging

1. Materials and Equipment

- Materials: BOPP (Biaxially Oriented Polypropylene) film.

- Equipment: Gravure printing press, electro-engraved cylinders (depths may be 20µm or 40µm).

2. Printing Parameters

- Printing Speed

-Case 1 (laminated CPP): 200m/min

-Case 2: 110m/min

- Dryer Length: 1.8m

- Dryer Temperature: 80°C

3. Printing Results

- High-definition print images with vibrant, rich colors.

- High-speed printing and high production efficiency.

7.2 Example 2: Eco-Friendly Water-Based Gravure Printing on Plastic Packaging Bags

1. Technical Features

- Uses water-based ink, offering eco-friendliness and pollution-free benefits.

- PET (Polyethylene Terephthalate) film as the printing layer, with degradable and decolorizable image structures.

2. Printing Steps

- Prepare the printing layer (PET film).

- Prepare water-based ink.

- Print water-based ink onto one side of the PET film using gravure printing equipment.

- Heat press the printed PET film onto the surface of plastic packaging bags, with the unprinted side of the PET film facing the plastic bag surface.

3. Printing Results

- Clear image structures with vibrant colors.

- Eco-friendly water-based ink reduces environmental impact.

7.3 Case Summary

These examples demonstrate different applications of gravure printing on plastic packaging products. The first case highlights the capability of achieving high-speed, high-quality prints on plastic films. The second case showcases the application.

8. Environmental Friendliness

The environmental friendliness of the plastic gravure printing process can be clearly analyzed and summarized from the following aspects:

8.1 Ink Usage

Solvent-Based Inks: Traditional plastic gravure printing processes heavily use solvent-based inks. These inks contain up to 50% volatile solvents, such as xylene and toluene. During printing, these solvents evaporate in large quantities, causing air pollution and potentially harming the health of operators.

Water-Based Inks: In recent years, with increased environmental awareness, the use of water-based inks in plastic gravure printing has gradually increased. Water-based inks do not contain harmful solvents, reducing air pollution and better complying with environmental regulations. However, due to issues with adhesion on plastic surfaces, color saturation, cost, and usage habits, over 70% of the flexible packaging sector still uses solvent-based inks.

8.2 Exhaust Emissions

Sources of Exhaust: During the printing process, gravure printing presses require high-powered infrared or electric heating to dry the inks, producing large amounts of exhaust gases. These exhaust gases contain volatile organic compounds (VOCs), which pollute the environment.

Emission Volume: Given the large ink volumes and high printing speeds of gravure presses, the emission volume is relatively high. Therefore, effective exhaust gas treatment measures must be taken during the gravure printing process to reduce environmental impact.

8.3 Wastewater Treatment

Sources of Wastewater: Wastewater generated during the gravure printing process mainly includes the waste water from cleaning plates and printing equipment. This wastewater contains ink and solvents, which can pollute the environment if discharged untreated.

Treatment Methods: Current methods for treating gravure printing wastewater include recycling solvents and adopting new environmental technologies. Solvent recycling is a relatively traditional treatment method but has limited recovery rates and may produce other pollutants. New environmental technologies, such as the NOAH Plasma Method, use plasma generated by high-voltage, high-frequency electric fields to decompose VOCs, offering higher treatment efficiency and lower energy consumption.

8.4 Industry Development Trends

Environmental Regulations: With increasingly strict environmental regulations, the gravure printing industry is gradually moving towards green and sustainable development. Companies need to comply with relevant regulations, take environmental measures, and reduce their environmental impact.

Technological Innovation: To reduce the environmental impact of gravure printing, companies need to continuously innovate and develop new technologies. This includes developing new eco-friendly inks, improving printing equipment and processes, and optimizing exhaust and wastewater treatment technologies.

The environmental friendliness of the plastic gravure printing process is influenced by various factors, including ink usage, exhaust emissions, and wastewater treatment. To reduce the environmental impact of gravure printing, a series of measures need to be taken, such as using water-based inks, reducing exhaust emissions, effectively treating wastewater, and innovating technologies. With increasingly strict environmental regulations and growing consumer demand for eco-friendly products, the gravure printing industry is gradually moving towards green and sustainable development.

9. Conclusion

9.1 Development Trends

Green and Sustainable Development: With the strengthening of environmental regulations and increasing consumer awareness of environmental protection, the plastic packaging industry is gradually moving towards green and sustainable development. The gravure printing process must keep pace with this trend by strengthening the development and application of environmental measures.

Technological Innovation: Through technological innovation, the gravure printing process can be continuously optimized to improve printing efficiency and quality while reducing environmental impact. This includes developing new eco-friendly inks, optimizing printing equipment and processes, and improving exhaust and wastewater treatment efficiency.

International Cooperation and Exchange: Strengthening cooperation and exchange with international peers to learn and adopt advanced environmental technologies and experiences can jointly promote the green development of the gravure printing process.

9. 2 Conclusion

While the plastic packaging industry’s gravure printing process provides high-quality printing results, it also faces challenges regarding environmental friendliness. By adopting a series of environmental measures and technological innovations, the environmental impact of the gravure printing process can be significantly reduced. With stricter environmental regulations and continuous technological advancements, it is believed that the gravure printing process will achieve more green and sustainable development in the plastic packaging industry.

At Package N’ Go, we provide top-tier custom packaging services designed to meet your specific requirements. Get in touch today, and let’s create something amazing together!