Poly mailers are an indispensable tool for any e-commerce business, and their lightweight and tough design makes them perfect for reliable delivery. But have you ever wondered how this smooth and flat poly mailer is produced? What kind of machinery and equipment would be used? In today’s blog post, I’m going to introduce you to one of the pieces of equipment used to produce poly mailers – the film blowing machine.

Film blowing machine makes it possible!

Film blowing machines are widely used to produce plastic films. From poly mailers as well as other basic everyday items to advanced medical solutions, film blowing machines make everything possible. Using precise settings and sophisticated technology, these machines create a wide range of plastic films suitable for many different applications. Through the careful configuration of the extruder die operation and proper selection of materials, a quality product is produced that can be trusted in any industry or field.

Three layers co-extrusion plastic film blowing machine for poly mailer production

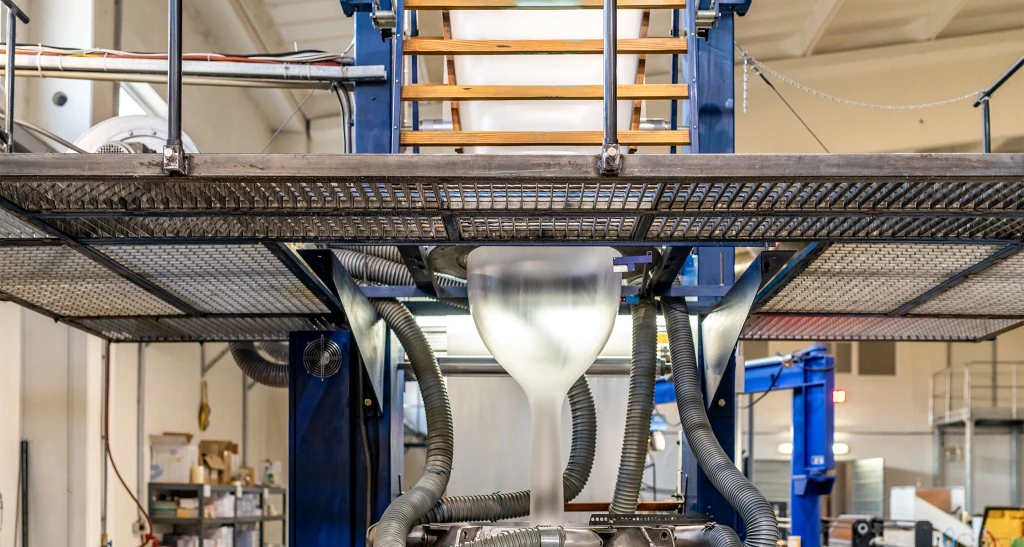

The poly mailers we use every day are usually laminated from three layers of film. At Package N’ Go, the equipment we use is called Three Layers Co-Extrusion Plastic Film Blowing Machine. The production line is packed with high-tech features like an efficient extrusion unit, IBC film bubble internal cooling system, and 360° horizontal upper traction rotation. We’ve even incorporated automatic deflection correction plus computer screen control! These modern updates mean poly mailer quality has been taken to the next level while boosting output and reducing energy consumption – making it easier than ever before for customers to get a perfect product every time. The poly mailer film produced has high transparency, puncture resistance, high toughness, good low-temperature heat cutting, good compound fastness, and anti-curl.

How is poly mailer film produced?

Poly mailer film is produced in an intricate process, beginning with the insertion of raw material into a hopper. The transport screw then melts and clears the mixture through a filter to ensure it meets quality standards. From there, bubbles are formed by extrusion which becomes flattened via take-up devices before being wound around rolls – ultimately creating smooth poly mailers that are ready for use.

High quality equipment with Package N’ Go

Package N’ Go has the latest and best equipment for producing poly mailers, ensuring that the poly mailers you receive from us are of international standard quality. Our machines are regularly inspected to ensure quality production and a consistent product. We take great pride in our poly mailers and guarantee that they will meet your needs perfectly.

Package N’ Go has the perfect custom mailer bags for your unique needs. Don’t miss out on our amazing shipping experience and great prices – explore now! Need a professional’s opinion? Our experts are here to provide valuable advice about custom packaging solutions, get in touch today.