Table of Contents

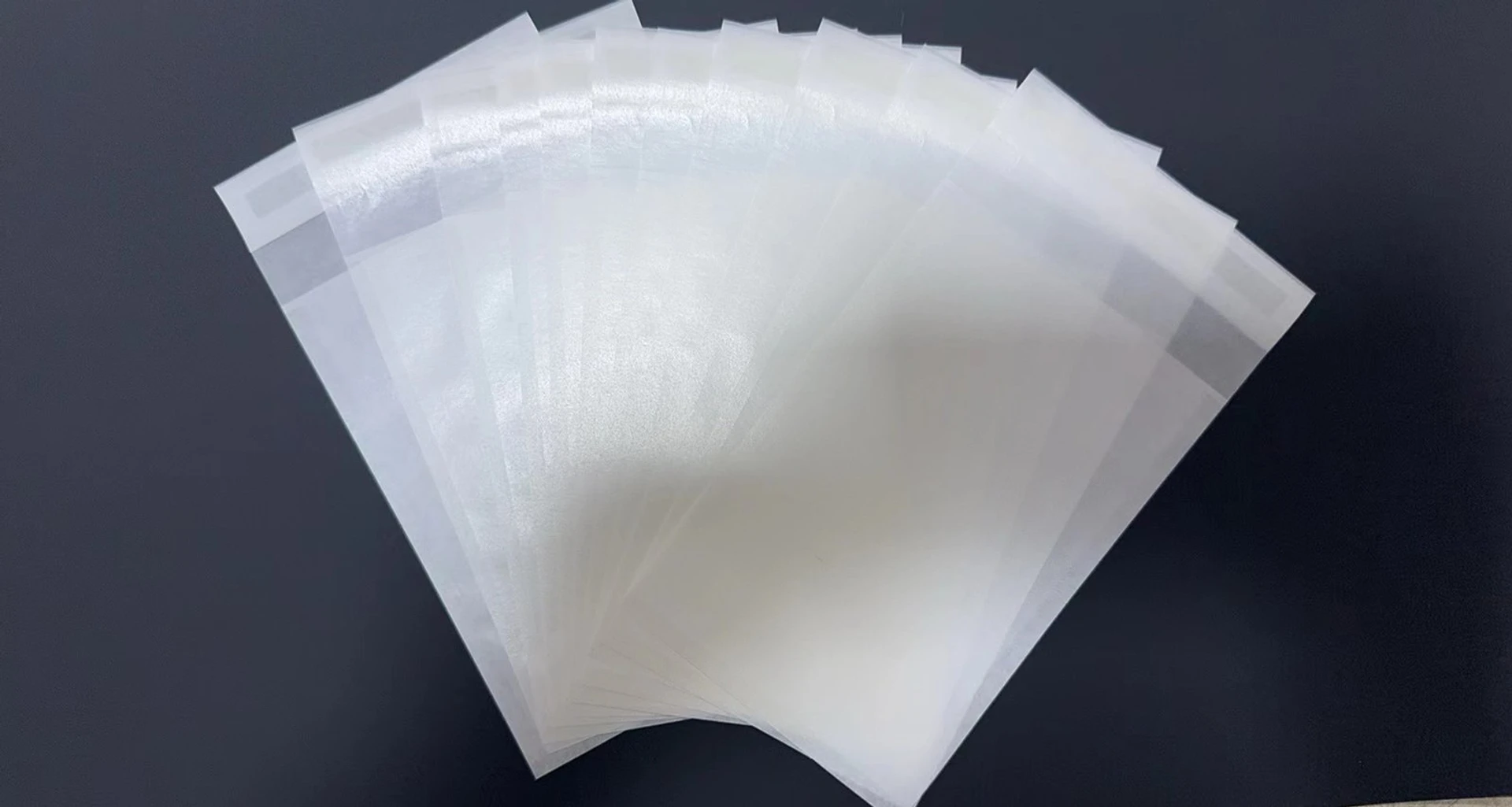

Glassine bags are an essential packaging solution in numerous industries due to their unique properties and versatility. Crafted from high-quality glassine paper, these bags are known for their dense, uniform texture, translucency, and resistance to high temperatures, moisture, and oil. Their eco-friendly nature, combined with their functionality and aesthetic appeal, makes them an excellent choice for businesses looking to enhance their packaging solutions.

This article explores the various uses, benefits, and production processes of glassine bags, as well as the factors influencing their pricing and quality standards, to help businesses understand how these bags can add value to their operations.

1. What is a Glassine Bag?

Glassine bags are crafted from glassine paper, a high-quality specialty material known for its dense, uniform texture and high internal strength. This paper is also characterized by its translucency, high temperature resistance, moisture resistance, and oil resistance. These features make glassine bags suitable for packaging in various industries, including food, clothing, electronics, home decor, and gifts.

2. What Are the Uses of Glassine Bags?

Glassine bags are versatile and widely used across various industries due to their unique properties. Here are some common uses:

Food Packaging: Glassine bags are popular for packaging food items like baked goods, nuts, candies, and dried fruits because they are grease-resistant and can keep the contents fresh.

Pharmaceuticals: They are used to package pharmaceuticals and medical products, offering protection from contamination and moisture.

Collectibles and Archival Storage: Glassine bags are ideal for storing and protecting collectibles such as stamps, coins, photographs, and other archival materials due to their acid-free and pH-neutral nature.

Stationery and Craft Supplies: These bags are used to package and organize stationery items like greeting cards, stickers, and craft supplies, ensuring they remain clean and undamaged.

Industrial Applications: In industrial settings, glassine bags are used to protect and separate small components, parts, and hardware during storage and transportation.

Art Supplies: Artists use glassine bags to protect their artwork, sketches, and prints from smudging and damage during storage and handling.

Cosmetics and Toiletries: Glassine bags are used for packaging small cosmetic products and toiletries, providing a moisture-resistant barrier.

Seeds and Agriculture: Farmers and gardeners use glassine bags to store and organize seeds, as they provide an excellent barrier against moisture and pests.

Retail and Gift Packaging: Retailers use glassine bags for packaging small gifts, jewelry, and other boutique items, offering a sleek and protective solution.

3. What Are the Benefits of Glassine Bags?

Glassine bags have a lot of benefits.Glassine bags offer numerous benefits, including transparency for easy identification of contents, durability with a dense texture and strong internal structure that provides excellent protection, and oil and water resistance to keep contents clean and extend their lifespan. Their versatility makes them suitable for a wide range of applications, while their smooth surface ensures clear and legible printing.

4. Are Glassine Bags Eco-Friendly?

Yes, glassine bags are eco-friendly due to their biodegradability, renewability, and low toxicity. They decompose naturally and are made from renewable resources.

5. What Factors Influence the Prices of Glassine Bags?

Several factors influence the prices of glassine bags, making the cost structure multifaceted. First, raw material costs are a major determinant, heavily influenced by the prices of pulp and associated transportation expenses. When the cost of raw materials rises, it directly impacts the overall price of the bags. Second, the quantity of bags ordered significantly affects the unit price; larger orders typically benefit from economies of scale, resulting in lower per-unit costs.

Additionally, the complexity of the production process plays a crucial role. More intricate designs or custom features can increase manufacturing expenses, thus raising the price. Market demand and supply fluctuations also have a notable impact. High demand or limited supply can drive prices up, while an oversupply or reduced demand can lower them.

Lastly, environmental policies are increasingly influencing production costs. Regulations aimed at reducing environmental impact can lead to higher manufacturing expenses, as companies may need to invest in sustainable practices and materials. All these factors combined create a dynamic pricing environment for glassine bags.

6. How Are Glassine Bags Made?

Glassine bags are made through a detailed and precise manufacturing process involving several key steps.

Printing

The process begins with layout design and plate making, where designs are created and adjusted to meet specifications. In the prepress preparation stage, plates are thoroughly checked, and materials are prepared to ensure everything is ready for printing. During the printing stage, ink is applied to the bags with careful attention to quality, ensuring the designs are clear and vibrant.

Composite

The composite process starts with gluing and bonding, where adhesive is applied to bond materials together. This is followed by heat pressing and curing, which uses heat to ensure strong and durable bonding. Finally, the cooling and shaping step quickly sets the shape of the bags, ensuring they maintain their form and structure.

Die Cutting

The die-cutting process begins with installing the die-cutting plate, setting up the machine to cut the bags to the desired shape and size. During the die-cutting operation, the materials are precisely cut and folded. Post-cutting processing involves additional steps such as hole punching or other customizations to complete the bags.

These combined processes ensure that glassine bags are made with high quality and precision, ready for their various applications.

7.What Is the Typical Turnaround Time for Glassine Bags?

The typical turnaround time for producing glassine bags can vary widely, ranging from a few days to several weeks. This variation depends on several factors, including the order size, with larger orders generally taking more time to produce than smaller ones. Customization requirements, like special sizes, shapes, or features such as die-cutting or spot UV printing, often involve more detailed and time-consuming procedures.

8. What Are the Quality Inspection Standards for Glassine Bags?

Quality inspection standards for glassine bags are comprehensive and ensure that each bag meets high-quality criteria before reaching customers. Key standards include printing quality, where designs must be clear, sharp, and free from smudges or misalignment. Bag dimensions are carefully checked to ensure they fall within acceptable deviation limits, maintaining consistency in size and shape. Sealing detail is critically inspected to guarantee proper sealing, ensuring the bags provide adequate protection for their contents.

Additionally, the bags are examined for structural integrity, ensuring there are no tears, weak spots, or defects. Material quality is assessed to confirm that the glassine paper is of the appropriate thickness and meets industry standards for durability and resistance to oil and water. These rigorous quality inspection standards help ensure that glassine bags are reliable, functional, and aesthetically pleasing, meeting the needs of various applications.

9. How Can Glassine Bags Help Your Business?

Glassine bags offer businesses a versatile and eco-friendly packaging solution with numerous benefits. Their durability, oil and water resistance, and transparency make them suitable for a wide range of industries, from food packaging and pharmaceuticals to collectibles and retail. By using glassine bags, businesses can ensure their products remain fresh, protected, and visually appealing.

Additionally, their biodegradability and renewable nature align with sustainability goals, enhancing a company’s environmental credentials. The detailed manufacturing process and strict quality inspection standards guarantee that each bag meets high standards of quality and reliability, contributing to overall customer satisfaction. The cost-effectiveness and customization options further add value, allowing businesses to efficiently tailor their packaging to specific needs, thereby improving brand presentation and operational efficiency.

Package N’ Go is a leading manufacturer offering customized premium packaging solutions. Contact us with your specific requirements to meet your packaging needs with precision and reliability.